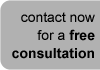

The term 'Fabrication' applies to operations, such as: cuttings, stamping and punching of natural sheet mica to specified size, shape, thickness and design within close dimensional tolerance for electrical and electronic end-users.

Normally, mica is fabricated with compound dies by foot or power punch process, especially if the finished piece contained perforation of any kind. A compound die punches the outside shape and all the inside holes with one stroke of the press most accurately. The compound die necessary for stamping natural sheet mica may be grouped in two general categories. One category comprises the highly complex dies required to produce Mica Spacers containing a number of perforations in various sizes and shapes for use in electronic tubes. The extremely critical dimensions and spacing of the perforations can be obtained only with fully designed and accurately constructed dies.

The other category of the compound dies is used in the production of not very complicated mica parts, such as:

Mica Insulators

Mica Condenser Plates

Mica Transistor Mounting Washers

Mica Baking Plates

Mica Discs

Mica Washers

Mica Shields

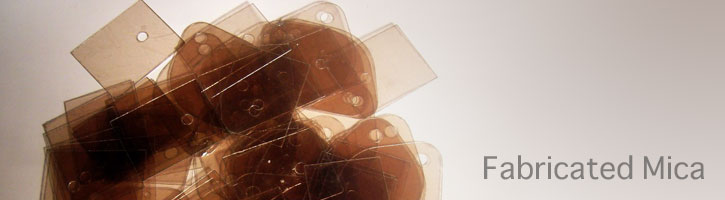

Cut Mica Plate

Stove Window

Mica Strainers